|

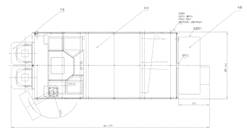

WX-6007 Auto Silicon Wafer Grinding Machine |

|

|

I Machine structure features and performance 1. This machine is designed with three working stations and two spindles, and the grinding is realized by turning worktable, rough grinding and fine grinding; 2. Turing working table is designed as “Vapour rotation – Vacuum fixation”; Grinding spindle system is constituted of grinding spindle, spindle seat, vertical pillar, and in-process measuring device for grinding force; Low friction cylinders on both sides of the spindle seat are used to balance the gravity of the spindle part and to increase the motion flexibility of the feed system; 4. Micro feed system is driven by servo motor through ball screw for grinding spindle for grinding and feed motion; Feed speed of this system, with 0.1 μm motion resolution, can achieve minimum 0.1 μm/s, and have a good response speed; 6. This machine is designed with auto position adjustment and thickness in-process measuring system; 7. There’s a micro adjustment device for the angle between grinding spindle and part spindle, so that to ensure the wafer’s surface shape; 8. This machine is designed with high precision and high reliability clamping positioning and conveying technology for the wafer, and with reliable automatic centering mechanism; A four-degree-freedom R-θ joint robot is used for wafer transport, so that realized the auto change between each working station. 9. This machine is designed with auto cleaning, drying and the auto cleaning for chuck, so that realize the wafer’s dry in and dry out in the grinding process; |

|

|

II

Machine technical specification and parameters Grinding wheel dia. 200mm Wafer transfer Manipulator Wafer chucking Vacuum adsorb Grinding wheel spindle number 2 Worktable number 3 Worktable cleaning Auto Worktable driven Electric spindle Min. feed rate 0.1μm Thickness measuring accuracy 0.1μm Grinding wheel speed 0~7000r/min Worktable rotate speed0~300r/min

Grinding wheel power 4.2kW Worktable spindle power 0.5kW

|

|

|

III

Working accuracy ≤ 3μm Wafer overall surface flatness(GBIR):

≤0.2μm ≤3μm Surface roughness after fine grinding: Ra≤10nm() |

|